Mocke lines pipelines with HDPE using the Sure-Line trenchless technology to extend the life of existing pipelines or for wear and chemical resistance of new pipelines. Continuous lined pipes save money on pipe spool sections with fewer flanges and possible leak points.

The corrosion and wear resistant HDPE liner for slurry, mining tailings, oil and gas, sewer and bulk water supply.

Mocke is the exclusive global licence holder from Polymeric Pipe Technologies (USA) for the Sure-Line technology.

Link : http://www.polymericpipe.com/

WHY USE SURE-LINE CONTINUOUS LINING?

- Rehabilitate pipelines from 200 mm to 1200 mm diameter

- Save on excavating costs

- Limited downtime

- Continuous lengths up to 1000m

- Save on steel flanges and HDPE stubs

- Rapid installation on site

- Fewer joints reduce chance of leaking

- Corrosion resistant

- Reduce flow friction with HDPE

- The HDPE liner has a SDR value of 30 – 40

- High pressures in pipelines are supported by the host pipe and not the liner

- The HDPE liner is held securely against the host pipe

The steel pipe is inspected and

cleaned using an air powered pig.

HDPE liners are butt welded together

on site into a continuous length.

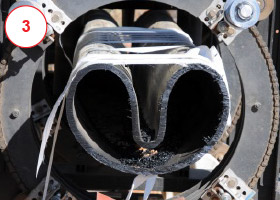

The HDPE liner pipe is formed

into a “C-Shape”.

The formed HDPE liner is winched

through the host pipe.

The pipe ends are

stub welded.

The HDPE liner is inflated returning

to its original shape for a tight fit.